About the service

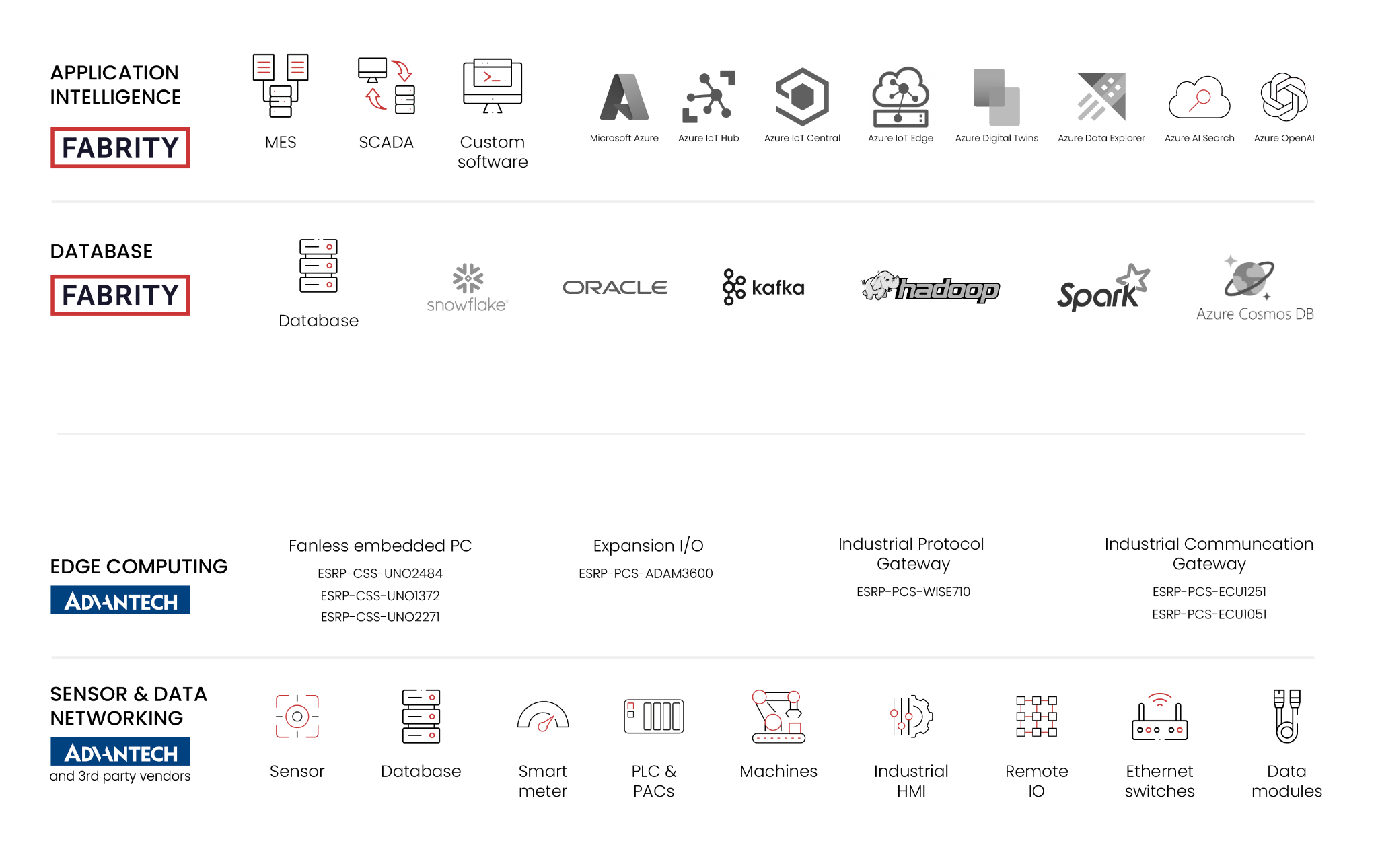

At Fabrity, we specialize in building IIoT networks from the ground up: from sensors, to gateways and edge devices, to cloud platforms, to custom software for industrial and manufacturing data analysis.

Together with our partner Advantech, a global leader in the fields of IoT intelligent systems and embedded platforms, we can help you pave the way toward Industry 4.0, empowering your plants with smart sensors, automation, and AI-powered solutions.

What we do

IIoT strategy and consulting

Develop tailored IIoT strategies to ensure a smooth transition to Industry 4.0, aligning with your business goals.

Sensor and device integration

Integrate sensors and devices into your infrastructure for seamless real-time monitoring and control.

Gateway and edge device implementation

Deploy and configure gateways and edge devices for local data processing and faster decision-making.

Custom software development

Create bespoke software solutions, including data engineering, data visualization, predictive maintenance, and automation.

Data engineering

Design and maintain robust data architectures for scalable and high-performance data analytics and machine learning.

Who we work for

An enterprise-grade energy management system (EMS) designed to optimize operational efficiency, support environmental, social, and governance (ESG) compliance, and improve energy performance. It allows organizations to monitor and manage various energy types—including electricity, gas, process heat, nitrogen, and compressed air—within a single, unified platform. By collecting and analyzing consumption data, the system helps companies take informed action to reduce energy use and operational costs.

Fully certified under ISO 50001, the EMS system ensures that energy data is structured, audit ready, and aligned with the requirements of the European Sustainability Reporting Standards (ESRS), particularly ESRS E1. This alignment makes it an essential tool for credible ESG reporting. Unlike systems with only declarative compliance, our system provides validated, reliable data that regulators and stakeholders can trust.

The system also includes an optional AI-powered chatbot assistant that enables users to interact with energy data using natural language—no technical knowledge required. Whether identifying anomalies, tracking consumption, or preparing reports, users can simply ask a question, and the assistant delivers clear insights.

Combined with its intuitive interface and low-code configurability, the energy management system empowers organizations to enhance transparency, automate energy oversight, and accelerate sustainability efforts.

Features and benefits

All-in-one utility monitoring

Track electricity, gas, heat, compressed air, and more from a single, centralized platform for full operational visibility.

Certified ESG compliance

Meet ESG and ESRS reporting standards with ISO 50001-certified data that’s audit ready and trusted by regulators.

Natural language AI assistant

Query energy data, generate reports, and uncover insights using a built-in chatbot—no technical skills required.

Anomaly detection made easy

Quickly identify irregular consumption patterns or system inefficiencies through smart, automated analysis.

Reliable data, real results

Base your sustainability strategy on verified, standards-compliant energy data—not on unverifiable declarations.

Streamlined reporting

Automate energy reporting processes and reduce manual effort in preparing ESG documentation and audits.

PHM is a solution to boost reliability and efficiency in smart factories. It monitors the condition of rotating machinery in real time using noninvasive, battery-powered sensors and wireless data transmission via LoRaWAN or Wi-Fi. This enables organizations to reduce unplanned downtime, extend asset life, and lower maintenance costs through early failure detection and just-in-time servicing.

The system uses AI-based analytics and ISO 10816/20816 vibration standards to assess equipment condition, deliver seven -day health predictions, and visualize trends via a user-friendly dashboard. It requires only 200 measurements to train models and can provide real-time insights within 24 hours of deployment. PHM supports both cloud-based and on-premises architectures for flexible integration with existing IT/OT environments.

Easy to implement and scalable, PHM is suitable for a wide range of industrial assets. It has been successfully deployed in factories and refineries, where it has improved safety, optimized inspection routines, and prevented costly breakdowns.

Features and benefits

Real-time machine insights

Continuously monitors equipment health using vibration data to detect anomalies before failures occur.

Noninvasive, rapid deployment

Wireless, battery-powered sensors enable quick and easy installation without interrupting operations.

Predictive maintenance intelligence

Delivers seven-day health forecasts based on AI analysis—minimizing unplanned downtime.

Flexible deployment options

Available as a cloud-based or on-premises solution, tailored to fit your IT/OT environment and data governance needs.

Easy-to-use visual dashboards

Presents health scores, alerts, and historical trends in an intuitive interface with optional photo or video views.

Proven ROI in real-world settings

Deployed in factories and refineries to reduce costs, improve safety, and streamline maintenance planning.

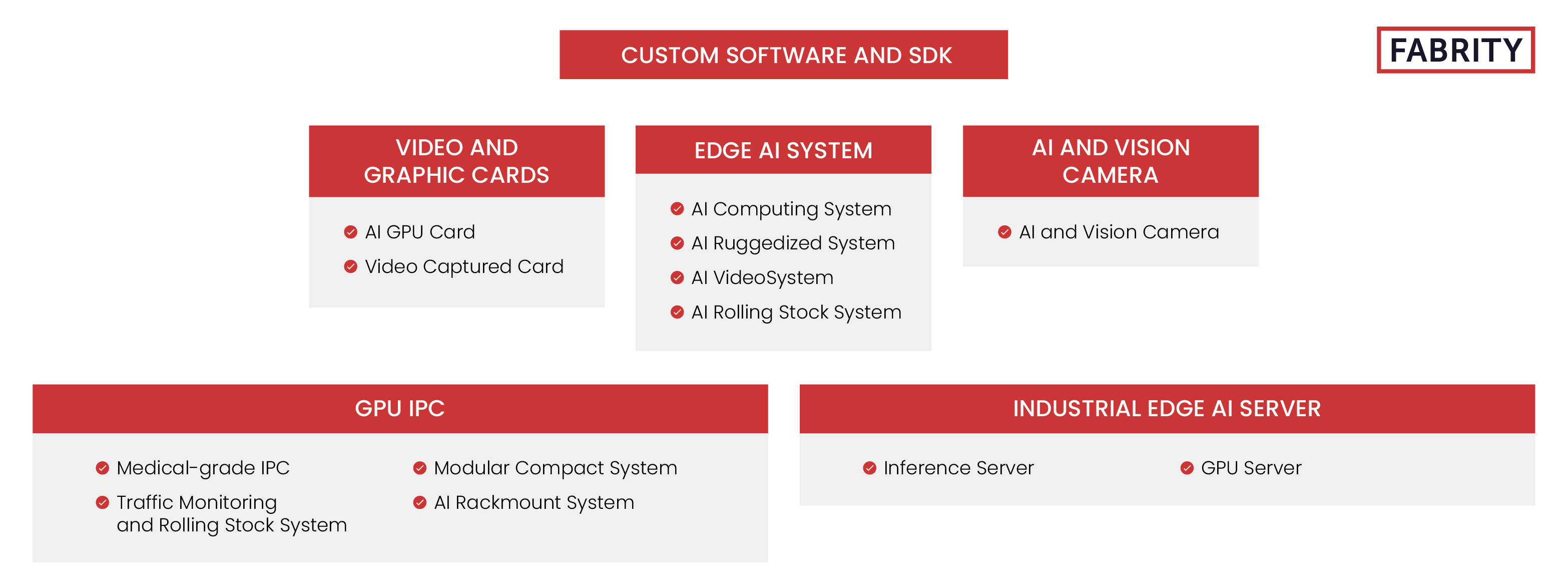

The solution: industrial edge AI and GPU solutions

Computer vision and edge AI enhance product quality and consistency through real-time analysis, reducing errors from manual inspections and ensuring uniformity in production. By automating repetitive tasks, these technologies increase throughput and accuracy while minimizing human fatigue, leveraging GPU-accelerated computations for optimal performance.

Built to withstand harsh industrial environments, edge AI and computer vision ensure continuous operation and improve worker safety by reducing the need for physical exposure in dangerous areas. Additionally, they minimize material waste with advanced defect detection and enable real-time equipment monitoring, supporting predictive maintenance to reduce unplanned downtime and boost overall equipment effectiveness (OEE).

Features and benefits

Enhanced quality and consistency

Computer vision and edge AI analyze quality in real-time, delivering consistent product checks and reducing the errors that arise from manual inspections.

Resilience in harsh environments

Edge AI and computer vision systems are designed to withstand extreme industrial conditions, ensuring continuous operation and worker safety without physical exposure.

Automation of repetitive tasks

These technologies streamline repetitive processes, reducing human fatigue and increasing both accuracy and throughput with GPU-accelerated computations.

Safety in hazardous areas

Computer vision and edge AI enhance monitoring in dangerous areas, detecting safety hazards automatically and keeping humans out of harm’s way.

Minimization of material waste

Advanced defect detection through GPU-powered computer vision systems significantly lowers waste in processes using costly materials, improving yield and efficiency.

Advanced equipment monitoring

Industrial edge AI and GPUs enable sophisticated, real-time equipment monitoring, facilitating predictive maintenance and enhancing overall equipment effectiveness (OEE) by minimizing unplanned downtime.

Agent Builder is an enterprise-grade platform for building conversational industrial AI agents. It enables the automation of industrial processes and real-time decision-making by integrating data from OT/IT systems, edge computing, and domain-specific knowledge into a single, intuitive low-code environment.

Thanks to integration with large language models (LLMs) and generative AI technologies, Agent Builder allows users to create intelligent applications and AI assistants without requiring advanced programming skills. Users can design agents that communicate with users via chat, respond to system events, and automate complex workflows.

Moreover, Agent Builder enables the creation of advanced diagnostic tools. Through integration with production systems (e.g., SCADA, MES, ERP) and access to domain knowledge, the platform supports maintenance departments in predictive maintenance tasks. Agents can analyze sensor data, identify anomalies, predict failures, and recommend service actions, significantly increasing the reliability and operational efficiency of industrial plants.

Features and benefits

Instant event response

Automatically react to real-time system events with intelligent agents that trigger workflows and deliver insights.

Smarter maintenance

Predict failures and reduce downtime by analyzing sensor data for anomalies and maintenance needs.

Simplified diagnostics

Quickly identify root causes and operational issues with AI-powered diagnostic tools.

Seamless system integration

Connect effortlessly with SCADA, MES, and ERP systems for full operational visibility.

Faster, better decisions

Turn complex industrial data into clear, actionable insights that drive efficiency and reliability.

Secure on-premises deployment

Deploy the platform locally to maintain full control over your data, ensuring it stays within your organization and protected from external access.

The IoT low-code platform is an advanced, scalable solution that accelerates the deployment of smart industrial systems and supports digital transformation. It brings together data from edge devices, IT/OT systems, and analytics applications into a unified environment—enabling real-time visibility, process automation, and data-driven decision-making across industrial operations.

The platform provides robust support for edge computing, cloud integration, live data and process visualization, and advanced analytics powered by AI and machine learning. It enables the creation of digital twins for production sites or distributed assets, offering a virtual representation of physical infrastructure for monitoring and optimization.

With its low-code architecture and support for over 450 industrial communication protocols—including Modbus, OPC UA, and MQTT—the IoT low-code platform ensures rapid deployment, seamless integration, and scalable operation across industries. It empowers organizations to streamline operations, boost performance, and accelerate their journey toward Industry 4.0.

Features and benefits

Real-time production supervision

Our IoT platform enables automation and real-time monitoring of production processes, in full compliance with Industry 4.0 standards.

Seamless data integration

It supports every communication protocol and can connect with all types of customer sensors and systems—including full integration with platforms like SAP.

Smart automation design

Users can build automation scenarios for production, administrative, and reporting processes, streamlining operations across departments.

Predictive maintenance capabilities

Advanced algorithms analyze historical data to anticipate issues before they occur, reducing downtime and improving equipment longevity.

Tailored to your needs

When out-of-the-box features are not enough, the system can be expanded and customized to match specific business goals and optimization requirements.

Unified data and analytics

Brings together edge, IT/OT, and analytics data into one scalable environment for real-time visibility and smarter decisions.

How we work

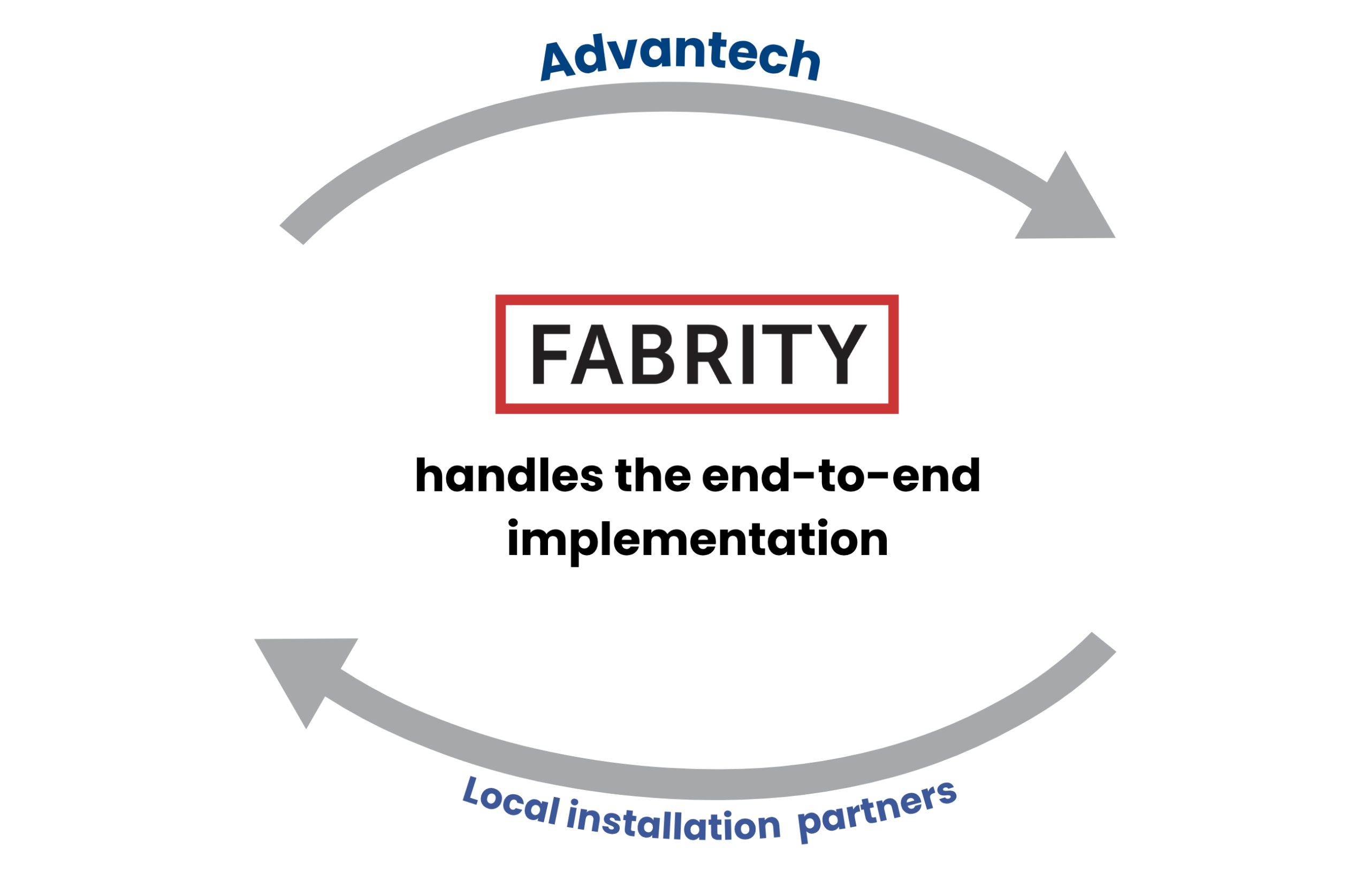

For software-only projects, Fabrity provides end-to-end services as a dedicated software development company.

In IIoT implementations, we manage the entire software layer while collaborating with trusted hardware providers like Advantech and local installation partners.

Most importantly, Fabrity takes full responsibility for the entire implementation process, ensuring seamless collaboration, project consistency, and high quality.

Need support with your data?

Get in touch to see how we can help.

Book a free 15-minute discovery call

Need help in building your IIoT network from the ground up? We are here to help. Just drop us a line.

.

Blog

IT vs. OT: bridging the gap with AI assistants

Learn how AI assistants help bridge the IT vs OT gap with smart data acquisition, real-time insights, and improved industrial control systems.

Industrial IoT communication protocols: a comprehensive guide to modern connectivity

Discover key IoT communication protocols, their security features, and how MQTT, OPC UA, and others ensure reliable, encrypted data exchange in industrial networks.

Data acquisition: the backbone of Industry 4.0 in 2025

Discover how data acquisition drives Industry 4.0 in 2025. Learn strategies for brownfield deployments, real-time monitoring, and optimizing industrial operations.