Nexen Suite

The industrial IoT platform for energy intelligence, prediction, and automation

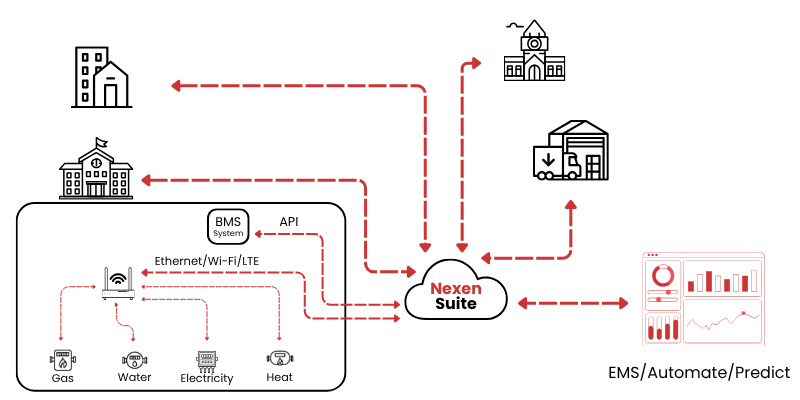

What is Nexen Suite?

Nexen Suite is an advanced industrial IoT platform designed for industry, smart cities, and large enterprises. It enables comprehensive monitoring and management of energy consumption across multiple locations, automation of device control, optimization of production processes, and predictive maintenance of industrial equipment. By leveraging real-time data analysis and intelligent machine learning algorithms, Nexen Suite reduces operational costs, improves energy efficiency, and ensures compliance with ESG requirements and the ISO 50001 standard.

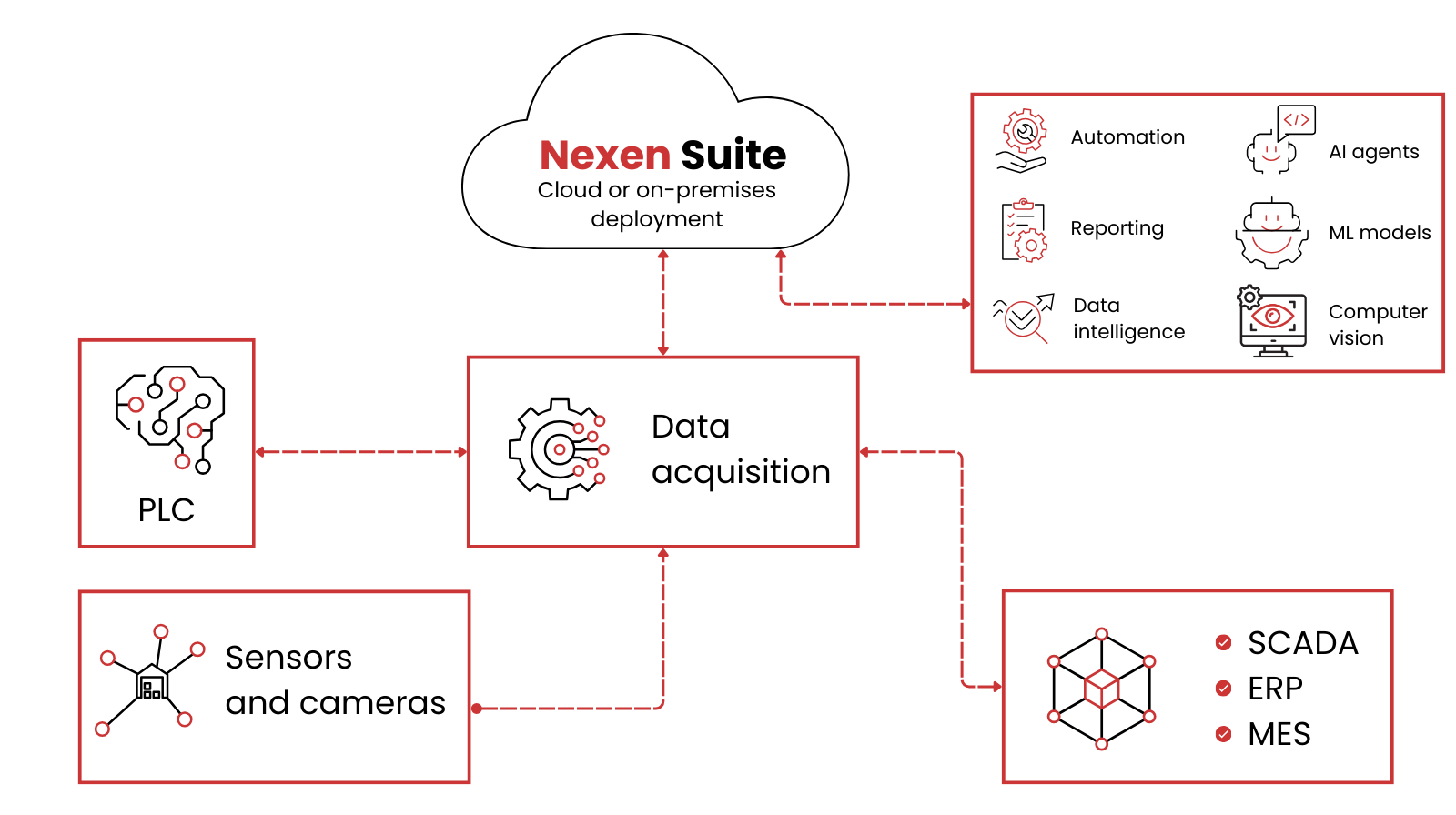

Nexen Suite architecture overview

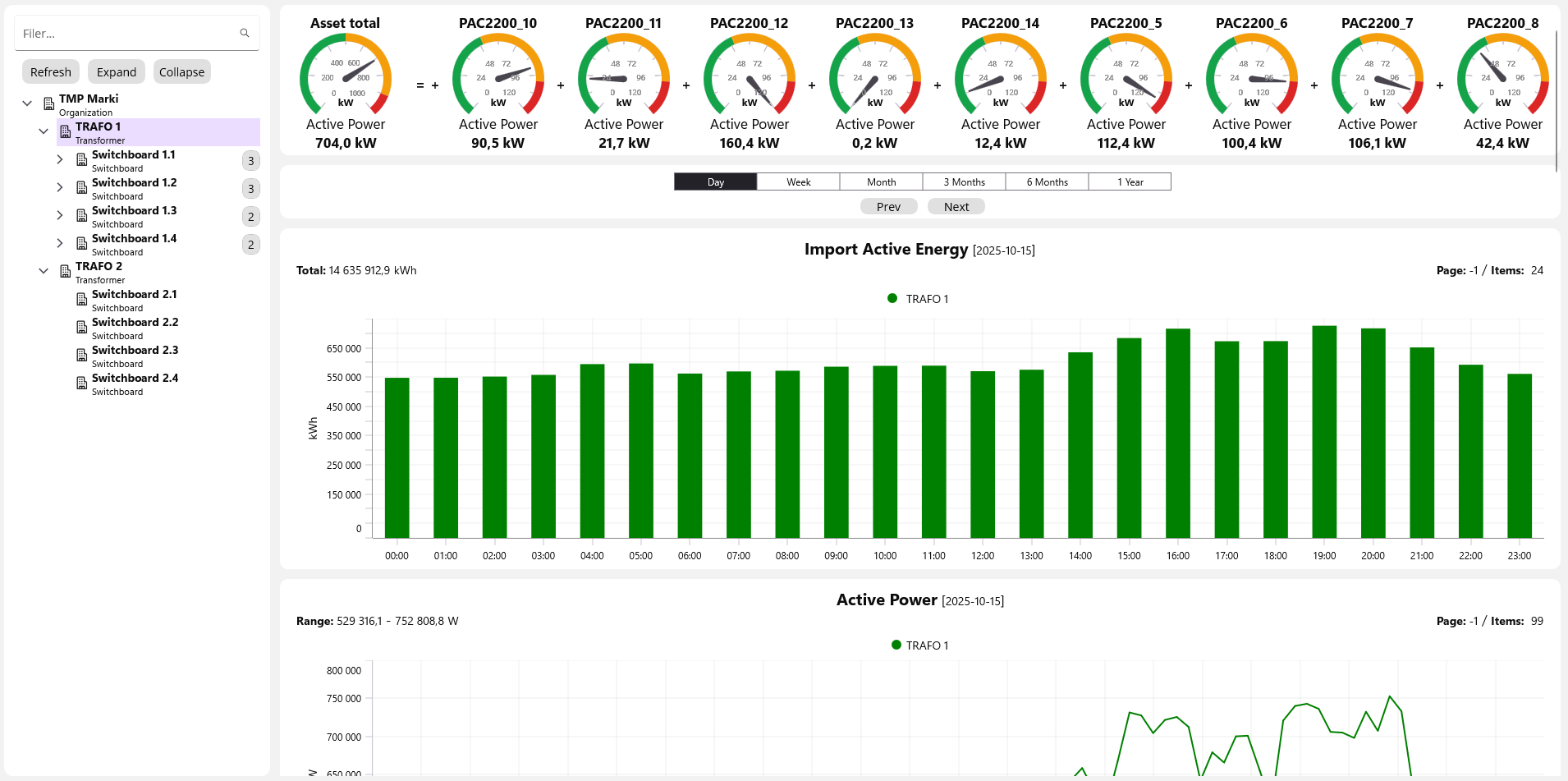

Nexen EMS

A comprehensive energy management system that monitors, analyzes, and optimizes energy consumption across multiple sites, helping organizations improve efficiency and reduce operational costs.

Nexen Predict

An AI-powered module that forecasts energy demand and prices and detects early signs of equipment failure based on data from vibration sensors—optimizing costs, preventing downtime, and extending the lifespan of industrial equipment.

Nexen Automate

A control automation module that manages devices such as HVAC and lighting systems in real time, maintaining optimal conditions while minimizing energy use.

Nexen Suite use cases

Who we work for

Our Nexen Energy Management System (EMS) is a comprehensive platform for monitoring, analyzing, and optimizing the consumption of electricity and other utilities such as water, gas, heat, compressed air, and technical gases. It combines smart metering, real-time analytics, automation, and sustainability reporting into one integrated solution.

At Fabrity, we deliver end-to-end EMS deployments—from field devices and data acquisition to integration with enterprise systems (ERP, MES, SCADA, BMS) and advanced analytics in the cloud.

Key features of Nexen EMS

Multi-utility monitoring

Track electricity, gas, water, heat, compressed air, and technical gases in one system.

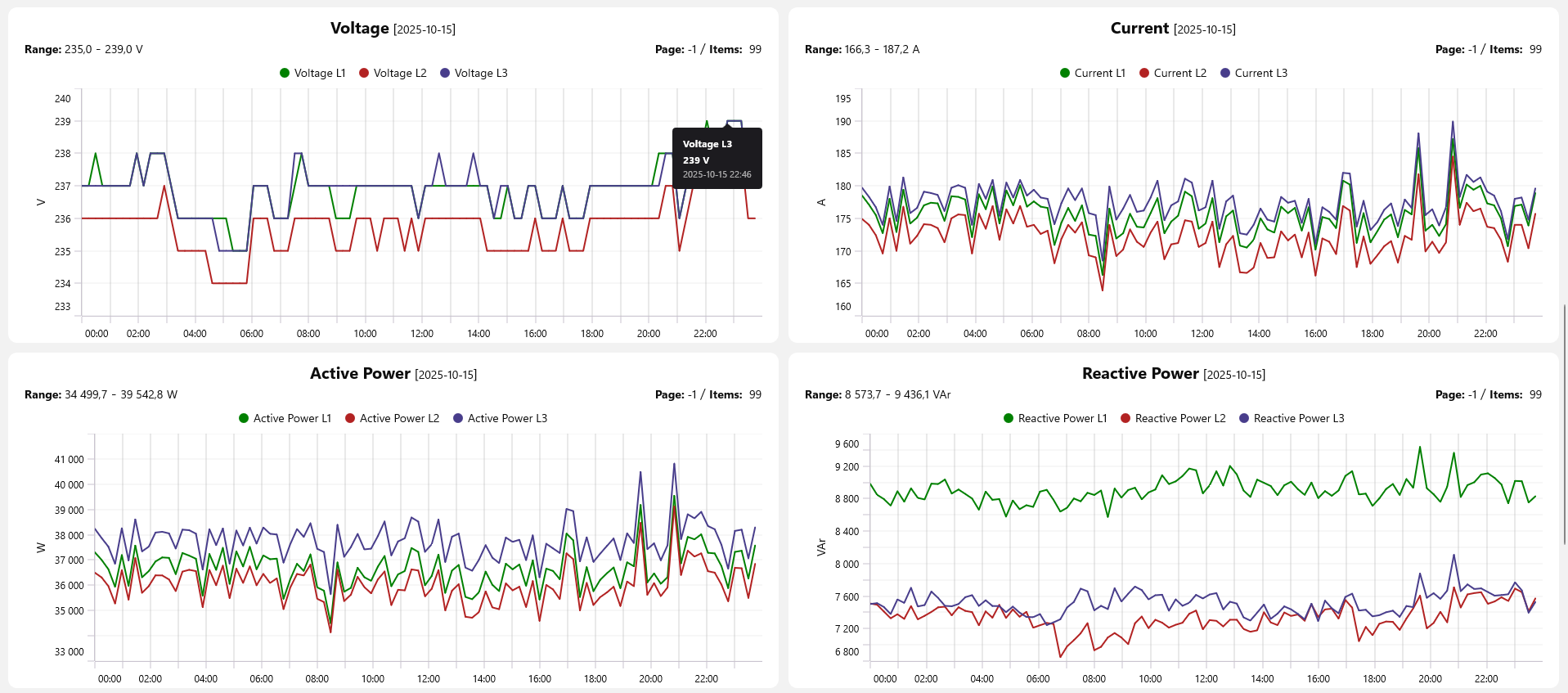

Power quality analysis

Monitor voltage, frequency, reactive power, phase angles, power factor and more.

Power Guard

Monitors active power minute by minute and alerts when limits are near or exceeded, preventing penalties and ensuring energy stability.

Optimization of contracted power

Helps define the real power profile and select the optimal contracted capacity, preventing oversizing and unnecessary costs.

Advanced live monitoring

Tracks dozens of parameters per meter in real time, providing deep insights into energy performance and equipment efficiency.

Multi-location monitoring

Provides centralized monitoring and analysis across multiple sites.

ESG and ISO 50001 compliance

Fully aligned with ISO 50001 energy management standards and ESG reporting frameworks.

Vendor-neutral integration

Integration with devices from multiple manufacturers (e.g., Siemens, Eastron, Advantech, Weidmüller).

Wide protocol support

Supports numerous communication protocols including Modbus, M-Bus, LoRa WAN, and Bluetooth.

System integrations

Connect seamlessly via API to BMS, SCADA, MES, ERP, SAP, and other enterprise systems.

Flexible deployment

Available as a cloud-based (Azure) or on-premises solution.

Cross-platform accessibility

Access via web, desktop, or mobile applications.

Nexen Predict is an advanced AI-powered solution designed for predictive maintenance and energy forecasting. It uses machine learning models to detect early signs of equipment failure based on data gathered by sensors—including triaxial vibrations, temperature, and other operational parameters—helping organizations avoid costly downtime and extend machinery lifespans.

The system also includes an AI model that forecasts energy price trends, indicating whether prices are likely to rise or fall. This allows companies to optimize production scheduling, particularly for energy-intensive processes, by aligning operations with the most cost-effective periods.

Part of the Nexen Suite, Nexen Predict integrates seamlessly with Nexen EMS for complete energy and operational management, but it can also be deployed independently to enhance existing infrastructures with predictive analytics and intelligent decision support.

Key features of Nexen Predict

Comprehensive sensor integration

Collects data from vibration, thermal, acoustic, and electrical sensors connected through industrial protocols such as Modbus, OPC UA, MQTT, and Ethernet/IP.

Anomaly and trend detection

Identifies anomalies and performance trends through real-time analysis of key operational parameters—voltage, frequency, temperature, humidity, CO₂ levels, and air quality.

AI-driven analytics and predictive maintenance

Uses machine learning models and pattern recognition to detect early signs of equipment failure and classify failure types, preventing unplanned downtime and extending asset lifespan.

Energy price forecasting

Forecasts dynamic price trends for electricity, gas, and other utilities to support smarter purchasing decisions and production planning.

Health index and diagnostics dashboard

Displays a dynamic “health score” for each machine, with trend graphs, alerts, and plant-wide status visualization to simplify diagnostics and maintenance prioritization.

Smart operations and resource planning

Optimizes scheduling of production and facility operations based on utility costs, tariffs, and predicted demand—particularly valuable for energy-intensive processes.

Integration with maintenance and enterprise systems

Automatically generates work orders and maintenance schedules in ERP or CMMS systems, with native integration to SCADA, MES, and other enterprise infrastructures.

AI-driven insights

Provides access to advanced analytics and expert knowledge through conversational AI agents, enabling intuitive data exploration and decision support.

Flexible deployment

Available as a cloud-based (Azure) or on-premises solution, easily integrating with existing IT and OT ecosystems.

Nexen Automate is a module within the Nexen Suite that can operate as part of a Nexen EMS deployment or as a fully independent solution. It enables intelligent automation of device control—including industrial machinery, HVAC systems, and lighting—across diverse operational environments.

When integrated with Nexen Predict, it can automatically activate or deactivate devices based on predictive insights (e.g., historical data, energy price trends, sensor data, etc.), driving greater energy efficiency, and cost optimization.

Key features of Nexen Automate

Automated device control

Enables precise automation of industrial devices and systems, improving operational efficiency while minimizing energy and resource usage.

Process and workflow automation

Automates repetitive and routine tasks, reducing human error and allowing staff to focus on supervision and higher-value activities.

Automated corporate reporting

Generates reports automatically by integrating with production and business systems such as BMS, SCADA, OEE, and ERP.

Operational optimization

Streamlines processes, reduces media consumption costs, and enhances productivity across industrial operations.

Vendor-neutral integration

Ensures full interoperability with controllers from leading manufacturers (e.g., Siemens, Eastron, Advantech, Weidmüller) without vendor lock-in.

Flexible deployment and scalability

Part of the Nexen Suite yet deployable as a stand-alone module, offering easy integration and scalability across diverse infrastructures.

Nexen Vision is an advanced computer-vision module within the Nexen Suite platform that brings AI-powered visual intelligence to industrial facilities. It enables automated quality inspection, real-time process monitoring, and enhanced safety through analysis of image and video streams. The solution combines machine learning, edge computing, and seamless system integration to support data-driven decision-making on the shop floor.

Key features of Nexen Vision

AI-driven visual inspection

Real-time process and equipment monitoring

Analyzes live camera streams to identify irregularities, bottlenecks, or abnormal machine behavior as they occur.

Safety and compliance detection

Monitors PPE usage, access to restricted zones, and potential safety hazards, supporting HSE compliance and proactive risk mitigation.

Edge and cloud inference

Runs computer-vision models on edge devices for low latency or in the cloud for scalability and centralized management

Custom model training and optimization

Supports training, tuning, and deploying custom AI models tailored to specific production processes or inspection criteria.

Seamless system integration

Connects through APIs to MES, SCADA, ERP, and QMS systems, enabling automated alerts, workflows, and reporting.

Nexen Suite use cases: Industry

Industrial environments are the primary domain where the Nexen Suite delivers its full potential, driving operational efficiency, optimizing production processes, reducing downtime, and generating significant cost savings across enterprises.

Scenario 1: Power Guard—active power limit control with Nexen EMS

In industrial facilities, exceeding contracted active power limits leads to costly penalties and operational disruptions. Maintaining power within defined thresholds is essential to control energy expenses and ensure network stability. key challenges include:

- Exceeding contracted active power limits, resulting in penalty charges.

- Lack of real-time awareness of approaching power thresholds.

- Difficulty forecasting power peaks during production cycles.

- Inability to automatically reduce or delay noncritical loads when limits are near.

- Manual monitoring that leads to delayed responses and unnecessary costs.

The solution: Nexen EMS power guard functionality

Nexen EMS introduces a dedicated Power Guard feature designed to continuously monitor active power and alert operators when predefined thresholds are approached or exceeded.

How it works:

- Real-time monitoring: Continuously tracks total active power across the facility, providing minute-by-minute insights into energy performance.

- Threshold-based alerts: Sends instant notifications (via SMS, email, or system dashboard) when power consumption reaches predefined warning or critical levels.

- Predictive peak detection: Uses trend analysis and historical data to forecast when active power will likely exceed the limit, allowing proactive intervention.

- Automated load control: Optionally integrates with control systems to temporarily reduce or shift nonessential loads (e.g., HVAC systems, auxiliary equipment) when thresholds are near.

- Customizable settings: Enables defining multiple limit levels (e.g., warning, critical, emergency) per production line, shift, or site.

- Integration with Nexen Predict: Combines with predictive analytics to anticipate power peaks based on production schedules, weather, or process data.

- Optimization of contracted power: Helps define the real power profile and select the optimal contracted level. Prevents oversizing that often costs more than occasional exceedance penalties.

Result:

With Nexen EMS Power Guard, companies can prevent power limit exceedances, reduce penalties, and ensure stable, efficient, and cost-effective energy management.

Scenario 2: Reactive power optimization with Nexen EMS

In industrial facilities, efficient energy management begins with understanding active and reactive power. While active power performs useful work, reactive power—though necessary for the operation of motors, transformers, and lighting systems—does not contribute to production.

Reactive power comes in two forms:

- Inductive reactive power generated by motors, transformers, and induction furnaces.

- Capacitive reactive power produced by LED lighting, UPS systems, long cables, and PV inverters.

When tg φ exceeds 0.4 or cos φ drops below 0.9, a power system becomes inefficient. Utilities then apply penalties for excessive reactive energy, both inductive and capacitive often adding 30–40% to the total electricity bill.

Consequences of excessive reactive power:

- Higher electricity costs and surcharges.

- Lower overall energy efficiency.

- Increased transmission losses and overheating.

- Transformer and cable overloads.

- Voltage fluctuations and poor power quality.

- Shortened equipment lifespan and risk of failure.

The Solution: Nexen EMS

Nexen EMS provides a complete solution for measurement, analysis, and optimization of reactive power. It continuously tracks cos φ, tg φ, voltage, current, and other power parameters—helping identify inefficiencies and sources of reactive power.

How it works:

- Monitors energy performance in real time.

- Automatically compensates or stores reactive power using capacitor banks or hybrid systems.

- Helps to maintain tg φ ≤ 0.4 and cos φ ≥ 0.9 to avoid penalties.

- Improves power quality and network stability.

- Extends the lifespan of your electrical infrastructure.

Result:

Lower costs, higher efficiency, and full control of your energy performance. With Nexen EMS, reactive power management turns from a hidden expense into a measurable business advantage.

Scenario 3: Energy optimization of production processes with Nexen EMS

In manufacturing, energy consumption represents one of the highest operating costs. Yet its optimization poses many challenges:

- Limited insight into energy usage by process or production line.

- Inability to track consumption trends or calculate performance differences.

- Power peak exceedances leading to costly penalties.

- No clear correlation between energy use and production output.

- Lack of defined KPIs and benchmarks to monitor improvement.

The Solution: Nexen EMS

Nexen EMS provides a complete, data-driven approach to monitoring, analyzing, and optimizing energy use across production processes. It transforms raw consumption data into actionable insights that directly improve efficiency and reduce costs.

How it works:

- Real-time visibility: Track energy usage by production line, process, or shift to identify inefficiencies and hidden losses.

- Trend analysis and benchmarking: Compare energy consumption over time to identify patterns, measure how usage changes between periods, and detect unusual spikes or drops that may indicate anomalies or inefficiencies.

- Peak load control: Monitor and manage peak power demand to prevent costly exceedances and grid overloads.

- Production–energy correlation: Integrate production data with energy metrics to measure true process efficiency and optimize schedules.

- Key performance indicators (KPIs): Define and monitor key metrics such as energy intensity (kWh per ton of product or per shift), cost efficiency, and compliance with predicted energy price trends.

- Data-driven decision-making: Use precise measurements to assign energy costs to specific products, processes, or shifts, enabling better budgeting and accountability.

Result:

With Nexen EMS, manufacturers can make smarter operational decisions, align production with energy economics, and achieve measurable improvements in efficiency, cost reductions, and improved sustainability.

Scenario 4: Energy price forecasting and predictive models with Nexen EMS + Nexen Predict

- Unpredictable fluctuations in electricity and gas prices on the energy market.

- Dependence on external conditions such as weather (temperature, sunlight, wind) and renewable energy supply.

- Lack of forecasting tools to anticipate price changes.

- Difficulty in aligning production schedules with favorable energy cost periods.

- Limited ability to plan budgets and energy procurement strategies.

The solution: Nexen EMS + Nexen Predict

Nexen EMS leverages advanced AI models to forecast dynamic energy prices and support smarter production and purchasing decisions. The goal is to deliver accurate short-term price forecasts, capturing both overall trends and daily fluctuations—so that companies can better plan operations and take advantage of favorable cost periods.

How it works:

- Machine learning–based forecasting uses dozens of parameters, combining market data such as energy prices, power demand, renewable energy generation, and system status with weather information (temperature, precipitation, cloud cover, and wind speed) to predict energy trends up to seven days in advance.

- Market trend analysis identifies expected rises and falls in energy prices, helping to plan production during the most cost-effective time windows.

- Smart production scheduling aligns energy-intensive processes with periods of lower energy costs.

- Strategic procurement supports purchasing decisions and contract negotiations based on reliable, data-driven forecasts.

Result:

By combining Nexen EMS with Nexen Predict, companies gain predictive insight into market dynamics, enabling proactive production planning, reduced energy spending, and greater operational resilience in a volatile energy market.

Scenario 5: Predictive maintenance with Nexen Predict

- Unplanned downtime disrupting production and delivery schedules.

- High maintenance costs due to reactive servicing and part replacements.

- Lack of real-time visibility into equipment health and operating conditions.

- Inability to detect anomalies early enough to prevent failures.

- Shortened asset lifespan caused by undetected mechanical stress or imbalance.

The Solution: Nexen Predict

Nexen Predict uses AI-powered predictive maintenance models to continuously monitor equipment condition and predict potential failures before they occur. By analyzing data from vibration, temperature, acoustic, and electrical sensors, the system identifies subtle deviations that indicate wear, imbalance, or malfunction.

How it works:

- Comprehensive sensor integration: Collects data from triaxial vibration, temperature, and other sensors via standard industrial protocols (Modbus, OPC UA, MQTT, Ethernet/IP).

- Anomaly and trend detection: Analyzes operational parameters in real time to detect abnormal behavior or performance degradation.

- AI-driven analytics: Uses machine learning and pattern recognition to classify failure types and estimate Remaining Useful Life (RUL) for each component.

- Health index dashboard: Provides an intuitive overview of each asset’s condition, displaying dynamic “health scores,” alerts, and performance trends.

- Maintenance integration: Automatically generates maintenance tasks and work orders in ERP or CMMS systems, enabling proactive scheduling.

Result:

With Nexen Predict, manufacturers move from reactive to predictive maintenance—reducing downtime, extending asset life, and optimizing maintenance costs.

Scenario 6: Automated quality inspection with Nexen Vision

In modern manufacturing environments, maintaining consistent product quality is essential for reducing scrap, minimizing rework, and protecting brand reputation. Manual inspection is labor-intensive, prone to human error, and often unable to keep up with high-speed production lines. Ensuring that every item meets strict quality standards requires precise, continuous, and automated visual control. Key challenges include:

- Defects or deviations going unnoticed due to the limitations of manual inspection.

- Difficulty detecting subtle surface irregularities, misalignments, or missing components.

- Inability to consistently inspect products at high line speeds.

- Lack of real-time feedback for operators when quality issues appear.

- High rejection rates and scrap costs due to late detection of defects.

The solution: automated quality inspection with Nexen Vision

Nexen Vision provides an AI-driven inspection system that continuously analyzes images from industrial cameras to detect quality issues the moment they occur.

How it works:

- Real-time defect detection: AI models analyze each product passing through the inspection point, identifying scratches, cracks, deformations, incorrect assembly, surface anomalies, and other defects.

- Instant alerts and operator feedback: When a nonconforming product is detected, the system sends immediate notifications to operators via dashboards, lights, sound signals, or integrations with existing MES/SCADA systems.

- Automated rejection mechanisms: The module can interface with actuators or PLCs to automatically remove defective items from the production line without interrupting workflow.

- Customizable inspection criteria: Each product type can have its own defect definitions, thresholds, and quality rules, easily configured through Nexen Suite.

- AI model training and continuous improvement: New defect samples can be used to retrain and refine detection models, increasing accuracy over time.

- Full traceability and analytics: Every detection event is logged with images, timestamps, and defect classification, enabling root-cause analysis and quality reporting.

Result:

With Nexen Vision, manufacturers gain reliable, real-time detection of quality issues, reducing scrap and rework while ensuring only compliant products move forward. This automated, AI-driven inspection improves efficiency, consistency, and overall production quality.

Scenario 7: Safety standards monitoring with Nexen Vision

Ensuring compliance with safety regulations is critical in industrial environments, where failure to follow protective equipment rules can lead to accidents, downtime, and legal consequences. Traditional supervision relies on manual observation, which is inconsistent and easily overwhelmed in large or complex facilities. Maintaining constant visibility into safety zones is a significant challenge. Key issues include:

- Difficulty verifying whether workers consistently wear required PPE (e.g., helmets, vests, goggles).

- Limited ability to monitor multiple safety zones simultaneously.

- Human oversight gaps, especially during busy shifts or in remote areas.

- Delayed response to unsafe behavior or unauthorized access.

- Inefficient manual reporting for incident analysis and compliance audits.

The solution: safety monitoring with Nexen Vision

Nexen Vision uses AI-powered video analysis to automatically detect whether individuals entering safety zones comply with required protective equipment standards.

How it works:

- PPE detection in real time: The system analyzes live camera feeds to verify if workers are wearing required gear such as helmets, high-visibility vests, goggles, or gloves.

- Instant alerts on noncompliance: When a person enters a designated safety area without proper equipment, Nexen Vision triggers immediate alarms or sends notifications to supervisors.

- Zone-based safety rules: Each monitored zone can have its own PPE requirements, access rules, and alert thresholds defined within Nexen Suite.

- Unauthorized access detection: Identifies individuals entering restricted zones or areas requiring special permission.

- Event logging and reporting: All incidents are recorded with timestamps and snapshots, supporting audits, root-cause analysis, and regulatory compliance.

- System integration: Works seamlessly with MES, SCADA, or security systems to automate responses such as stopping equipment or locking access points.

Result:

Nexen Vision helps maintain a safer workplace by automatically detecting PPE violations and unauthorized access, enabling quick intervention and supporting consistent compliance with safety standards.

Nexen Suite use cases: Corporate

In today’s sustainability-driven economy, corporations must go beyond reducing energy costs to meet ESG and ISO 50001 requirements. The Nexen Suite enables organizations to monitor, automate, and report energy performance across multiple sites—turning sustainability goals into measurable, data-driven results.

Corporate energy and ESG reporting with Nexen EMS and Nexen Automate

For large organizations, especially those with multiple locations such as corporate offices, production plants, public utility buildings, energy management is no longer just about cost reduction. The priority is now ESG compliance, ISO 50001 certification, and demonstrating measurable progress in sustainability and environmental responsibility. Key challenges include:

- Lack of consistent data across multiple sites and facility types (e.g., corporate

- Limited visibility into consumption by key systems such as HVAC, lighting, and plug loads.

- Difficulty in calculating CO₂ emissions and the organization’s overall energy mix (coal, renewables, biomass, hydro).

- No standardized reference metrics—energy use is not normalized per square meter or per building zone.

- Pressure from ESG frameworks to prove measurable improvement in efficiency and sustainability, not just cost savings.

The Solution: Nexen EMS + Nexen Automate

Together, Nexen EMS and Nexen Automate create an intelligent, automated ecosystem for energy monitoring, control, and reporting, supporting both ESG and ISO 50001 requirements.

How it works:

- Multi-site energy monitoring: Aggregates data from hundreds of locations (e.g., hospitals, clinics, gyms, dental facilities) into one centralized dashboard.

- Automated device control (Nexen Automate): Manages HVAC systems, lighting, and power circuits automatically to optimize energy use in real time.

- Standardized benchmarking: Compares consumption per square meter, per floor, or per site to identify outliers and set performance baselines.

- System-level analysis: Breaks down usage by HVAC, lighting, and outlets, helping pinpoint areas for efficiency improvement.

- Lighting optimization: Monitors lighting loads and automates LED upgrades or control schedules to demonstrate clear reductions.

- Time-based trend reporting: Analyzes energy use across seasons and years to showcase verified efficiency improvements.

- ESG and ISO 50001 compliance: Calculates emissions using actual energy data and supplier energy mix (coal, renewables, biomass, hydro) to provide accurate CO₂ reporting.

- Smart automation integration: Links Nexen Automate with Nexen EMS, allowing intelligent responses to changing conditions (e.g., automatically reducing lighting or HVAC use during low occupancy or peak tariffs).

Result:

By combining Nexen EMS and Nexen Automate, organizations gain a unified platform that monitors and actively controls energy use—achieving ESG compliance, ISO 50001 certification, lower emissions, and greater operational efficiency across all facilities.

Nexen Suite use cases: Smart city

Cities around the world are under growing pressure to reduce energy consumption, cut emissions, and modernize aging infrastructure. The Nexen Suite empowers municipalities to transform their urban ecosystems into efficient, data-driven environments through intelligent monitoring, automation, and predictive analytics.

Smart city energy optimization with Nexen EMS, Nexen Automate, and Nexen Predict

Modern cities manage hundreds of public buildings, schools, hospitals, offices, and administrative facilities, which collectively consume vast amounts of energy. Despite this scale, municipalities often lack real-time insight into energy usage and cannot easily identify where and why inefficiencies occur. Key challenges include:

- No centralized monitoring of energy use across multiple public facilities.

- Outdated infrastructure, such as traditional lighting systems (e.g., 100W tungsten bulbs) or inefficient HVAC equipment.

- Wasted energy due to lights or systems left running overnight.

- Limited visibility into consumption trends and maintenance needs.

- Difficulty in correlating energy use with external factors such as temperature, weather, and occupancy.

- Lack of predictive models for simulating and optimizing building performance at the city scale.

The Solution: Nexen EMS + Nexen Automate + Nexen Predict

The Nexen Suite, powered by Nexen EMS, Nexen Automate, and Nexen Predict, provides cities with a comprehensive toolset for monitoring, analyzing, and optimizing public infrastructure energy use.

How it works:

- IoT-based monitoring: Connects thousands of devices and sensors across schools, hospitals, and offices, enabling real-time tracking of electricity, lighting, heating, and HVAC performance.

- Energy benchmarking: Measures consumption per square meter and compares facilities across the municipal network to identify inefficient buildings.

- Lighting modernization: Detects outdated light sources and quantifies potential savings from LED retrofits and automated lighting control.

- Automation and control (Nexen Automate): Automatically adjusts HVAC and lighting systems based on occupancy, daylight, and tariff schedules, reducing unnecessary consumption.

- Predictive simulation (Urban Digital Twin): Uses energy, weather, and environmental data to create digital models of city buildings, testing scenarios like weekend HVAC reduction to optimize comfort and energy balance.

- Data-driven maintenance: Identifies facilities requiring modernization and prioritizes retrofits for the highest energy return.

- Centralized insights: Delivers unified dashboards for mayors, city engineers, and energy managers to track performance, savings, and emissions across the entire city portfolio.

Result:

By combining monitoring (Nexen EMS), automation (Nexen Automate), and AI-based simulation with Nexen Predict powering an Urban Digital Twin, municipalities can reduce energy waste, modernize infrastructure, and meet ISO 37122 smart-city standards—building greener, more efficient, and more intelligent urban environments.

Tech stack

Fabrity oversees the complete implementation of the Nexen Suite—from software configuration to system integration—while relying on local installation partners solely for the hardware layer to ensure seamless deployment and reliable connectivity.

More specifically, Fabrity delivers the software layer of the Nexen Suite, covering the entire technology stack from application intelligence (MES, SCADA, custom software) to data management, AI, and cloud integration.

- smart power meters,

- data concentrators and gateways,

- environmental and utility sensors,

- edge communication gateways,

- industrial Ethernet switches and servers.

Smart Power meters

Data concentrators and gateways

Environmental and utility sensors

Industrial Ethernet switches and servers

Advantech, Weidmüller, Siemens, Eastron, and other vendors

How we work

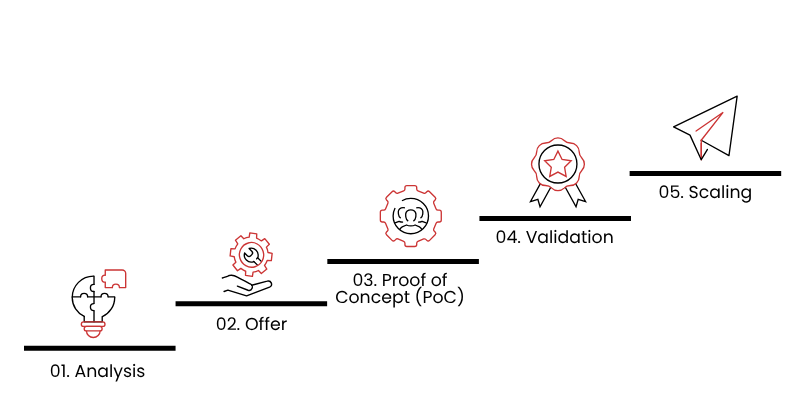

01. Analysis—understanding the client’s needs.

02. Offer—preparing a value proposition.

03. Proof of Concept (PoC)—a test implementation to verify assumptions.

04. Validation—assessing the benefits of the PoC and optimizing the solution.

05. Scaling—full-scale implementation of EMS Suite.

Book a call

Looking to optimize your operations with data-driven energy intelligence?

Discover how Nexen Suite can help you get there.

Blog

IT vs. OT: bridging the gap with AI assistants

Learn how AI assistants help bridge the IT vs OT gap with smart data acquisition, real-time insights, and improved industrial control systems.

Industrial IoT communication protocols: a comprehensive guide to modern connectivity

Discover key IoT communication protocols, their security features, and how MQTT, OPC UA, and others ensure reliable, encrypted data exchange in industrial networks.

Data acquisition: the backbone of Industry 4.0 in 2025

Discover how data acquisition drives Industry 4.0 in 2025. Learn strategies for brownfield deployments, real-time monitoring, and optimizing industrial operations.